Standard Conveyor System

Leading Manufacturers, Exporters and Wholesaler of ARB Conveyor System, Chain Conveyor System, Flat Belt Conveyor System, Flexi Link Conveyor System, Gravity Roller Conveyor System, Knife Edge Conveyor System, Modular Conveyor System, Pallet Roller Conveyor System, Power Roller Conveyor System, Slat Chain Conveyor System, Spiral Conveyor System, Take Up Conveyor System, Telescopic Conveyor System, Through Belt Conveyor System, Vertical Lifter Conveyor System, Weighing Conveyor System and Z Type Conveyor System from Pune.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | ARB |

| Belt Material | Low friction Acetyll |

| Frame Material | SS304/MS |

| Belt Width | 76mm to 2286mm |

| Belt Length | As per product/Customized |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Speed | Upto 60m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | All Four Direction |

We Rothe Packtech are leading manufacturer and supplier of Activated Roller Belt Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Flexible to handle, multiple product sizes without any changeover

- Needs less floor space

- Increases system reliability

- Eliminate costly control system

- Reduce complexity

- Handles small products easily

- Variable speed conveyance

- Create gap between products

- Lateral movement for both side

- 90° product Rotation

Application :

- Scanning and sorting

- Rejection station

- Retail Industry

- Warehouse

Activated Roller Belt Conveyors: Revolutionizing Material Handling Globally

Material handling is a critical aspect of various industries in India. To streamline this process, Rothe Packtech introduces Activated Roller Belt Conveyors. Below, we will explore the innovative world of Activated Roller Belt Conveyors and how they reshape material handling.

What Sets Activated Roller Belt Conveyors Apart?

Activated Roller Belt Conveyors are a breakthrough in material handling technology. They feature a unique design with individually powered rollers that can be selectively activated or deactivated. This design allows unprecedented control over conveyed products, making them highly versatile and adaptable.

In What Way Do Activated Roller Belt Conveyors Improve The Efficiency Of Material Handling?

Efficiency is paramount in material handling operations, and Activated Roller Belt Conveyors excel in this regard. These conveyors offer precise control over product orientation, alignment, and routing. Whether diverting, merging, aligning, or sorting, these conveyors provide a level of flexibility and accuracy previously unattainable.

How Does Rothe Packtech Meet Specific Material Handling Requirements?

Every industry has unique material handling requirements, and Rothe Packtech understands this. They collaborate closely with clients to customize Activated Roller Belt Conveyor solutions tailored to specific needs. Whether optimizing processes for a specific product or automating complex sorting tasks, Rothe Packtech ensures that Activated Roller Belt Conveyors adapt seamlessly.

How Does Rothe Packtech Prioritise Material Handling Security?

Safety is paramount in material handling operations, and Rothe Packtech leaves no stone unturned. Activated Roller Belt Conveyors have advanced safety features, including emergency stop mechanisms, sensors, and protective guards. These measures minimize the risk of accidents and ensure a secure working environment for operators.

How Does Rothe Packtech Promote Environmental Responsibility In Material Handling?

Sustainability is a growing concern today, and Rothe Packtech addresses it with their Activated Roller Belt Conveyor systems. These systems are designed with proper efficiency in mind and reducing power consumption. By minimizing waste and energy usage, Rothe Packtech contributes to a greener and more sustainable future for material handling operations.

What Does The Future Hold For Activated Roller Belt Conveyors?

As industries in Pune and beyond continue to demand greater precision, flexibility, and efficiency in material handling, the future of Activated Roller Belt Conveyors looks promising. Rothe Packtech remains committed to innovation, continuously enhancing the capabilities of Activated Roller Belt Conveyors to meet evolving industry needs.

With a strong presence in Pune and a growing nationwide reach, Rothe Packtech is poised to lead the way in Activated Roller Belt Conveyor technology. These conveyors are set to play a pivotal role in the future of material handling, empowering businesses to achieve higher levels of efficiency, precision, and sustainability.

Final Words

Activated Roller Belt Conveyors represent a leap forward in material handling technology. Rothe Packtech's expertise in manufacturing these advanced systems positions the company as a leader in Pune, India, and the broader Indian market. With a focus on efficiency, customization, safety, and sustainability, Rothe Packtech's Activated Roller Belt Conveyor solutions are revolutionizing material handling processes and driving industries toward a more efficient and sustainable future.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Usage | Industrial |

| Voltage | 220V |

| Phase | Single Phase |

| Country of Origin | India |

Chain Conveyors: New Generation Material Handling with Rothe Packtech

Innovation is the key to efficiency in material handling, and Chain Conveyors are at the forefront of this revolution. Rothe Packtech, a trusted name in conveyor systems, is reshaping the landscape of material transport with its advanced Chain Conveyor solutions. But what makes Chain Conveyors the go-to choice for businesses in India? Let's delve into this groundbreaking technology and discover the answers.

What Are Chain Conveyors and How Do They Work?

Chain Conveyors are pivotal in modern material handling, serving as efficient and reliable transport systems. These conveyors consist of a chain-driven loop with powered rollers or slats that move items from one point to another. The chain propels the load, making it a dependable and robust choice for material transport.

What Industries Benefit Most from Chain Conveyors?

Chain Conveyors find their application across various industries, making them versatile and indispensable. FMCG, Manufacturing, automotive, food and beverage, agriculture, and logistics industries rely on Chain Conveyors for their material handling needs. These conveyors excel when goods' continuous and reliable movement is paramount.

How Do Chain Conveyors Contribute To Enhance Production Efficiency?

Chain Conveyors are pivotal in improving efficiency by ensuring the seamless and continuous flow of materials or products. These conveyors offer several advantages that contribute to enhanced material handling efficiency:

- Precise Control:Chain Conveyors provide precise control over the movement of items. Whether in the automotive industry, where parts must be precisely positioned for assembly, or in logistics, where packages need to be accurately sorted, the controlled movement of Chain Conveyors minimizes errors and improves overall efficiency.

- High Throughput: Chain Conveyors can handle large volumes of materials or products, making them ideal for high-throughput applications. This capacity ensures that material handling processes can keep pace with production demands.

- Customization: Chain Conveyors can be customized to meet the unique needs of various industries. Whether you're transporting heavy machinery components or fragile goods, the adaptability of Chain Conveyors ensures they can be customized to suit specific requirements.

- Reduced Labor: By automating material transport, Chain Conveyors reduce the manual labor requirements in material handling processes. This improves efficiency and minimizes workplace injuries and fatigue-related errors.

- Why Choose Rothe Packtech's Chain Conveyors Over Competing Brands?

Rothe Packtech's Chain Conveyors have earned a stellar reputation in Pune and beyond for several compelling reasons as follows:

- Customization: These conveyors can be tailor-made to suit the unique needs of various industries, making a proper fit into your existing processes.

- Reliability: Rothe Packtech's Chain Conveyors are built to last, minimizing downtime and maintenance costs. Their robust construction ensures longevity and uninterrupted material transport.

- Innovation: Rothe Packtech is committed to staying at the cutting edge of conveyor technology. Their Chain Conveyors incorporate the latest advancements to meet evolving industry demands.

- Support: With a responsive customer support team, Rothe Packtech ensures your material handling operations run smoothly. Any technical issues are addressed promptly, ensuring minimal disruptions.

Can Chain Conveyors Be Customized to Fit Unique Material Handling Needs?

Absolutely! Rothe Packtech understands that every industry and business in India has specific material handling requirements. That's why they offer customized Chain Conveyor solutions. Whether you need to transport bulk materials, delicate products, or anything in between, Rothe Packtech can tailor these conveyors to meet your precise needs.

Final Words

Rothe Packtech's Chain Conveyors are not just machines but the architects of a new era in material handling. With a steadfast focus on customization, reliability, innovation, and safety, Rothe Packtech's Chain Conveyor solutions are redefining the essence of material transport in Pune and beyond.

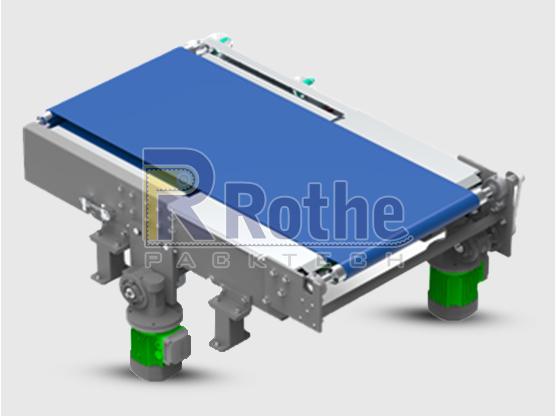

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 220V/380V/415V |

| Country of Origin | India |

| Conveyor Type | Flat Belt |

| Frame Material | SS304/MS |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Speed | Upto 60m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Flat Belt Conveyor / Mold Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- High Speed

- Smooth running

- Easy Maintenance

- Easy Belt Replacement

- Long width

Application :

- Product Accumulation

- Precision part Movement

- Part handling and Positioning

- Automated and Manual Assembly Line

- Injection molding machine outlet

Flat Belt Conveyors: Redefining Material Transport Across The Nation

In the fast-paced world of industrial operations, where efficiency and reliability are paramount, Flat Belt Conveyors have emerged as a game-changer. Rothe Packtech, a trusted name in conveyor systems, is spearheading the revolution in material transport with these conveyors. But what makes Flat Belt Conveyors so exceptional? It's their design, precision, and adaptability that set them apart.

How Do Flat Belt Conveyors Elevate Material Transport Efficiency?

Flat Belt Conveyors redefine efficiency by providing precise control over product movement. These conveyors offer unmatched versatility and accuracy, whether loading, unloading, or transferring items from one point to another. They are the linchpin of streamlined material transport processes.

Why Choose Rothe Packtech’s Flat Belt Conveyors over Standard Conveyors?

Flat belt conveyors provide a considerable advantage over standard conveyors from other manufacturers. Here are the critical advantages of Rothe Packtech’s Flat Belt Conveyors:

- Precision Control: Flat Belt Conveyors offer precise control over product movement, reducing errors and improving overall efficiency.

- Easy Customization: These conveyors can be customized to fit the needs of various industries and applications.

- Proper Safety: Advanced safety features, including emergency stop mechanisms and protective guards, ensure a secure working environment.

- Enhanced Sustainability: Flat Belt Conveyor systems are designed with energy efficiency and waste reduction in mind, contributing to a greener future.

- Can Flat Belt Conveyors Be Customized to Fit Unique Material Transport Needs?

One size doesn't fit all in the complex world of industrial processes. Rothe Packtech understands this, which is why they offer tailored solutions. Flat Belt Conveyor systems can be customized to meet specific requirements, making them a versatile choice for industries of all kinds. Whether you're transporting fragile goods or heavy loads, these conveyors adapt seamlessly, offering a solution that integrates seamlessly into your operations.

Is Safety a Top Priority in Material Transport with Flat Belt Conveyors?

Safety is non-negotiable in material transport operations, and Rothe Packtech takes it seriously. Flat Belt Conveyors come equipped with advanced safety features. These include emergency stop mechanisms, real-time monitoring sensors, and robust protective guards. These measures create a secure working environment, allowing operators to focus on productivity without safety concerns looming overhead.

How Do Flat Belt Conveyors Promote Sustainability in Material Transport?

In an era where sustainability is paramount, Rothe Packtech's Flat Belt Conveyor systems are designed with energy efficiency and waste reduction in mind. By minimizing energy consumption and waste generation, these systems contribute to a greener and more sustainable future for material transport operations. This commitment to sustainability aligns perfectly with the global shift toward environmentally conscious practices.

What Lies Ahead for Flat Belt Conveyors in the Material Transport Industry?

As industries in Pune and beyond evolve, the demands for material transport solutions grow. Flat Belt Conveyors are well-positioned to meet these evolving needs head-on. Rothe Packtech's unwavering commitment to innovation ensures these conveyors remain relevant and pioneering.

Flat Belt Conveyors shine as a beacon in a future where precision, adaptability, and efficiency will be non-negotiable. They represent the next chapter in the ongoing story of material transport, where adaptability and sustainability work harmoniously to propel industries toward even greater productivity and success.

Final Words

Flat Belt Conveyors aren't just machines but the architects of a new era in material transport. Rothe Packtech's expertise in manufacturing these cutting-edge systems positions them as pioneers in India and global leaders. With a relentless focus on efficiency, customization, safety, and sustainability, Rothe Packtech's Flat Belt Conveyor solutions are redefining the very essence of material transport.

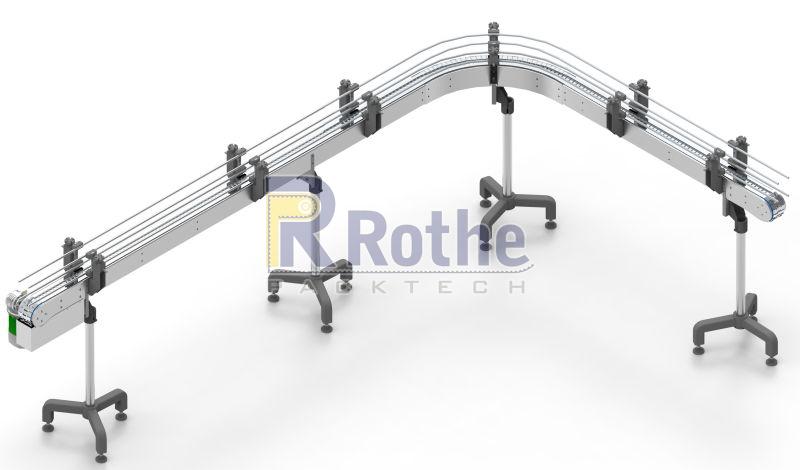

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Conveyor Type | Flexi Link |

| Belt Material | Acetyll(POM) |

| Frame Material | SS304/MS |

| Belt Width | 63mm, 83mm, 103mm |

| Belt Length | Customized |

| Conveyor Profile | Straight/Curve |

| Height | As per Requirement |

| Speed | Upto 70m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Flexi Link Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- High Speed Capability

- Easy to Assemble and Install

- Flexible mounting for accessories

- Low noise Level

- Robust Design

- Easy to clean

- Washable (Optional)

Application :

- Liquor Industry

- Dairy Industry

- Packaging Industry

- Pharma Industry

- Switchgear Industry

- Printing

- Labelling

Level Up Your Material Handling Capabilities with Rothe Packtech's Flexi Link Conveyors

In material handling, flexibility, efficiency, and reliability are paramount. Enter Flexi Link Conveyors, a game-changing innovation redefining how businesses in India and beyond manage their material handling needs. Below, we delve into the world of Flexi Link Conveyors and explore how Rothe Packtech, the leading Flexi Link Conveyor Manufacturer, is making waves in this arena.

What Sets Flexi Link Conveyors Apart From Traditional Conveyors?

Flexi Link Conveyors are versatile solutions that adapt to various material handling requirements. These conveyors feature a modular design with interconnected links forming a flexible and adaptable conveyor belt. This innovative design allows easy customization, making them suitable for various applications, from packaging to production lines.

What Makes Rothe Packtech’s Flexi Link Conveyors a Game-Changer in Material Handling?

In the bustling industrial landscape of Pune and across India, material handling is the heartbeat of productivity. Rothe Packtech has unveiled a groundbreaking solution – the Flexi Link Conveyor. But what sets these conveyors apart? Their innovative design features individually powered rollers that can be selectively activated or deactivated. This ingenious design offers unparalleled control over conveyed products, making Flexi Link Conveyors versatile and adaptable.

How Do Flexi Link Conveyors Redefine Efficiency in Material Handling?

Efficiency is the game's name in material handling, and Flexi Link Conveyors take it to a new level. With precise control over product orientation, alignment, and routing, these conveyors redefine flexibility and accuracy. Whether it's about merging, diverting, aligning, or sorting, Flexi Link Conveyors ensures operations run seamlessly and efficiently.

How Does Rothe Packtech Ensure Safety In Material Handling?

Safety is non-negotiable in material handling operations. Rothe Packtech prioritizes safety by equipping its Flexi Link Conveyors with advanced safety features. These include emergency stop mechanisms, sensors, and protective guards to minimize the risk of accidents and create a secure working environment for operators.

Can Flexi Link Conveyors Be Customized for Unique Material Handling Needs?

In the intricate world of industrial operations, one size never fits all. Rothe Packtech understands this implicitly. Instead of offering cookie-cutter solutions, they collaborate closely with clients to craft Flexi Link Conveyor systems tailored to precise needs. This translates into streamlined processes, automated sorting tasks, and seamless adaptation to ever-evolving industry demands.

What Does The Future Hold For Flexi Link Conveyors?

As businesses seek more adaptable, efficient, and customizable material handling solutions, the future of Flexi Link Conveyors appears promising. Rothe Packtech, as the top Flexi Link Conveyor Manufacturer, remains committed to innovation, continually refining its Flexi Link Conveyor designs to meet evolving industry needs.

With a strong presence in Pune, India, and a growing footprint nationwide, Rothe Packtech is poised to lead the way in Flexi Link Conveyor technology. These conveyors are set to play a pivotal role in the future of material handling, empowering businesses to achieve higher efficiency, productivity, and safety standards.

Final Words

Flexi Link Conveyors have become a cornerstone of modern material handling. Rothe Packtech's expertise in manufacturing these adaptable systems positions the company as a leader in Pune and the broader Indian market. With a focus on efficiency, customization, safety, and sustainability, Rothe Packtech's Flexi Link Conveyor solutions are the key to elevating material handling processes to new heights.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Gravity Roller |

| Frame Material | SS304/MS |

| Conveyor Width | 400mm to 1200mm |

| Conveyor Length | Customized |

| Conveyor Profile | Straight/Incline |

| Height | As per Requirement |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Gravity Roller Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Cost Effective in terms of power

- Easy to install

- Low Maintenance

Application :

- Retail Industry

- Warehouse

Gravity Roller Conveyor: Revolutionizing Material Transport with Simplicity

In the dynamic world of material transport, where efficiency, reliability, and innovation reign supreme, Gravity Roller Conveyors have emerged as a testament to the power of simplicity. Rothe Packtech, a pioneering Gravity Roller Conveyor manufacturer, is at the forefront of transforming material handling across Pune and beyond. What makes Gravity Roller Conveyors remarkable, and how do they redefine the future of material transport? Join us on this captivating journey through the world of conveyance, where gravity takes the lead.

Why Choose Rothe Packtech as Your Gravity Roller Conveyor Manufacturer?

- Innovation through Simplicity: Rothe Packtech believes in the elegance of simplicity. Their Gravity Roller Conveyors are a testament to this philosophy, offering efficient and reliable material transport without complex automation.

- Tailored Solutions: Just as no two industries are the same, Rothe Packtech understands that no material transport needs are identical. Their Gravity Roller Conveyors are highly customizable, ensuring they meet your requirements.

- Trust and Confidentiality: At Rothe Packtech, building lasting relationships founded on trust and confidentiality is paramount. They tackle your challenges with discretion and precision, prioritizing your success.

Can Gravity Roller Conveyors Be Customized to Fit Unique Material Transport Needs?

In a world where individuality reigns supreme, Rothe Packtech recognizes the importance of adaptability. Their Gravity Roller Conveyor systems are not only versatile but also highly customizable. This flexibility ensures that the conveyors seamlessly integrate into your operations, regardless of your unique material transport needs.

Is Reliability a Key Aspect of Rothe Packtech's Gravity Roller Conveyor Design?

Reliability is the cornerstone of Rothe Packtech's Gravity Roller Conveyor design. These conveyors are engineered with meticulous care to deliver unwavering performance. With fewer components, there are fewer points of failure, resulting in consistent and dependable material transport.

How Do Gravity Roller Conveyors Promote Sustainability in Material Transport?

In an era where sustainability is imperative, Rothe Packtech's Gravity Roller Conveyor systems stand out as environmentally friendly options. They require no external power source, reducing energy consumption and contributing to cost savings. They align seamlessly with the global shift toward sustainable industrial practices by simplifying material transport.

What Makes Gravity Roller Conveyors Integral to Modern Material Transport?

- Effortless Movement: Gravity Roller Conveyors utilize the force of gravity to move materials from one point to another effortlessly. This simplicity reduces energy consumption and fewer moving parts, contributing to long-term cost savings.

- Zero Power Requirements: Unlike powered conveyors, Gravity Roller Conveyors require no external power source. They rely solely on gravity and manual assistance, making them a cost-effective choice.

- Low Maintenance: With fewer components prone to wear and tear, these conveyors demand minimal maintenance, reducing downtime and servicing costs.

- Versatility: Gravity Roller Conveyors can accommodate a wide range of materials, turning them into an ideal choice for various industries, including manufacturing, and distribution.

What Lies Ahead for Gravity Roller Conveyors in the Material Transport Industry?

As industries evolve, the demand for efficient, reliable, eco-friendly material transport solutions is ever-present. Gravity Roller Conveyors are well-equipped to meet these evolving needs. Rothe Packtech's commitment to simplicity and innovation ensures that these conveyors will continue to shape the future of material transport.

Final Words

Gravity Roller Conveyors prove that the most straightforward solutions are sometimes decisive. Rothe Packtech's expertise in manufacturing these straightforward yet effective systems positions them as pioneers in India and global leaders. With their unwavering focus on simplicity, customization, reliability, and sustainability, Rothe Packtech's Gravity Roller Conveyor solutions are redefining the very essence of material transport.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Knife Edge |

| Belt Material | PVC/PU/Rubber |

| Frame Material | SS304/MS |

| Belt Width | 150mm to 500mm |

| Belt Length | Customized |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Speed | Upto 60m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Knife Edge Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Transfer small Product

- High Speed

- More application safety

Application :

- Food Industry

- Pharma Industry

- Cross Transfer

- Switchgear Industry

- Dairy Industry

Knife Edge Conveyors: Redefining Precision Material Transport

In the intricate world of material transport, Knife Edge Conveyors have emerged as trailblazers, and Rothe Packtech, a prominent Knife Edge Conveyor Manufacturer, stands at the forefront of this transformation. What makes Knife Edge Conveyors a game-changer, and how are they revolutionizing precision material transport?

Why Are Knife Edge Conveyors the Epitome of Precision?

- Ultra-Thin Profile: Knife Edge Conveyors are designed with an ultra-thin profile, ensuring minimal gaps and precise material handling, especially for small, delicate items.

- Unparalleled Versatility: These conveyors offer remarkable versatility and adaptability, making them suitable for various materials, including irregularly shaped items.

- Precision Redefined: Knife Edge Conveyors provide precise control over material movement, resulting in reduced product damage and increased operational accuracy.

What Advantages Do Rothe Packtech’s Knife Edge Conveyors Bring Over Traditional Models?

Rothe Packtech's Knife Edge Conveyors offer an array of advantages, setting them apart as the preferred choice for precision material transport:

- Reliability Beyond Compare: These conveyors are engineered for unwavering reliability, minimizing downtime and ensuring consistent productivity.

- Custom to Perfection: Rothe Packtech's Knife Edge Conveyors can be customized to fit to the specific needs of various industries and applications, providing unprecedented flexibility.

- Safety as a Top Priority: Advanced safety features, including emergency stop mechanisms and comprehensive protective measures, create a secure working environment.

- Championing Sustainability: Rothe Packtech's Knife Edge Conveyor systems prioritize energy efficiency and waste reduction, contributing to a greener and more sustainable future.

Can Knife Edge Conveyors Be Tailored to Address Unique Material Transport Challenges?

In material transport, one size certainly does not fit all. Rothe Packtech recognizes this and offers tailor-made solutions. Knife Edge Conveyor systems can be customized to meet the specific demands of various industries, ensuring seamless integration into your operations. Whether you're handling fragile goods or irregularly shaped products, these conveyors adapt effortlessly to cater to your unique needs.

Is Safety Paramount in Rothe Packtech’s Knife Edge Conveyor Design?

Safety is the bedrock of material transport operations, and Rothe Packtech takes it extremely seriously. Knife Edge Conveyors from Rothe Packtech have advanced safety features, including emergency stop mechanisms, real-time monitoring sensors, and robust protective guards. These measures create a secure working environment, allowing operators to focus on productivity without compromising safety.

How Are Knife Edge Conveyors Contributing to Sustainability in Material Transport?

In an era where sustainability is imperative, Rothe Packtech's Knife Edge Conveyor systems are designed with energy efficiency and waste reduction as top priorities. By minimizing energy consumption and waste generation, these systems play a vital role in advancing a greener, more sustainable future for material transport operations. This commitment aligns seamlessly with the global shift towards environmentally conscious industrial practices.

What Does the Future Hold for Knife Edge Conveyors in Material Transport?

As industries evolve and the demands for precision material transport continue to grow, Knife Edge Conveyors remain at the forefront. Rothe Packtech's unwavering dedication to innovation ensures that Knife Edge Conveyors stay at the cutting edge of technological advancement.

Knife Edge Conveyors represent machines and a new era in precision material transport. Rothe Packtech's expertise as the best Knife Edge Conveyor Manufacturer positions them as pioneers in India and global leaders. With their unwavering focus on efficiency, customization, safety, and sustainability, Rothe Packtech's Knife Edge Conveyor solutions are redefining the essence of precision material transport.

| Business Type | Manufacturer, Exporter, Supplier |

| Belt Material | Polyamide/Polypropylene/Acetyl(POM) |

| Voltage | 220V/380V/415V |

| Belt Length | Customized |

| Belt Width | 200mm To 1200mm |

| Country of Origin | India |

| Conveyor Type | Modular |

| Frame Material | SS304/MS |

| Conveyor Profile | Straight/Curve/Incline |

| Height | As per Requirement |

| Speed | Upto 70m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | one/bidirectionall (Optional) |

We Rothe Packtech are leading manufacturer and supplier of Modular Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit

- Smooth running at high speed

- Low noise level

- Easy to modified and expand

- Flexible mounting for accessories

- Fully UHMW support

- Easy to assemble

- Easy cleaning

- Excellent performance

- Ergonomic design

- Washable (Optional)

Application :

- Secondary Packaging of food products

- Pouches

- Plastic Bags

- Shrink Wrap Product

- Card Board Box

- Plastic Container

- Pharma Industry

- Dairy Industry

- Retail

- Warehouse

Upgrade Your Material Handling Efficiency with Rothe Packtech's Modular Conveyors

In the bustling world of industrial operations, where efficiency, adaptability, and precision are the currency of the trade, Modular Conveyors have emerged as a transformative force. Crafted with precision by Rothe Packtech, the leading Modular Conveyor Manufacturer, these conveyors are rewriting the material handling rules. Their modular design makes them exceptional, which allows for unparalleled versatility and customization.

How Do Modular Conveyors Elevate Material Handling Efficiency?

Modular Conveyors take efficiency to a whole new level. They offer precise control over product movement, whether merging, diverting, aligning, or sorting. These conveyors redefine the very essence of adaptability and accuracy, ensuring that operations run like a finely tuned orchestra.

Can Modular Conveyors Be Customized to Unique Material Handling Needs?

In the intricate industrial processes, one size seldom fits all. Rothe Packtech understands this, so they offer more than just off-the-shelf solutions. They provide an innovation partnership. Modular Conveyor systems can be tailored to precise requirements, making them a versatile choice for industries of all kinds. Whether dealing with delicate items or robust products, these conveyors adapt seamlessly, offering streamlined processes and automated sorting tasks.

Is Safety a Priority in Material Handling with Modular Conveyors?

In the fast-paced material handling world, safety is not just a checkbox; it's a paramount concern. Rothe Packtech prioritizes safety by equipping Modular Conveyors with advanced safety features. These include emergency stop mechanisms, sensors for real-time monitoring, and protective guards that create an impenetrable shield against accidents.

With safety as the foremost consideration, Modular Conveyors provide a secure working environment for operators, allowing them to focus on productivity and efficiency without the specter of mishaps looming over their heads.

Are Modular Conveyors Energy Efficient?

Rothe Packtech's Modular Conveyor systems are designed for energy efficiency and waste reduction. By minimizing power consumption and waste generation, these systems contribute to a greener and more sustainable future for material handling operations. This commitment to sustainability aligns perfectly with the global shift towards environmentally conscious practices and resonates with a new generation of environmentally aware consumers.

What's the Future for Modular Conveyors in the Material Handling Industry?

As industries in Pune and beyond continue to change, so do the demands placed on material handling solutions. Modular Conveyors are poised to meet these evolving needs head-on. Rothe Packtech's unwavering commitment to innovation ensures these conveyors remain relevant and pioneering.

In a future where precision, flexibility, and efficiency will be non-negotiable, Modular Conveyors shine like a beacon. They represent the next chapter in the ongoing story of material handling, where adaptability and sustainability harmoniously coexist to drive industries toward greater productivity and success.

Final Words

Modular Conveyors aren't just machines but the architects of a new era in material handling. Rothe Packtech's expertise as the leading Modular Conveyor Manufacturer positions them as pioneers in India and as global leaders. With an unwavering focus on efficiency, customization, safety, and sustainability, Rothe Packtech's Modular Conveyor solutions are redefining the core of material handling. The future of material handling has arrived, and it's modular.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Frame Material | SS304/MS |

| Conveyor Width | According to Pallet Size |

| Conveyor Length | Customized |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Motor | Bongfiglioli/SEW/ABB/Elecon/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Pallet Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Rugged and durable enough to handle the heaviest products

- Sprocket rollers and roll to roll chain system provides positive driving power to the product

- Spcially Used for palletizer

Application :

- Retail Industry

- Warehouse

- Agriculture Industry

Pallet Conveyor: Elevating Material Transport for a Productive Future

In the ever-evolving landscape of material transport, Pallet Conveyors have become the backbone of industries worldwide. Rothe Packtech, a trusted and pioneering Pallet Conveyor manufacturer, is leading the way in transforming material transport in Pune, India, and beyond. But what makes Pallet Conveyors indispensable, and how do they redefine the future of material transport? Let's embark on this exciting journey through innovation, efficiency, and excellence.

Can Pallet Conveyors Be Customized to Suit Unique Material Transport Needs?

In an industrial world filled with diversity, Rothe Packtech recognizes the importance of flexibility. Their Pallet Conveyor systems are not only versatile but also exceptionally customizable. This adaptability ensures that industries with varying demands can find tailored solutions seamlessly integrating into their operations. Whether it's the delicate handling of items or the robust transport of heavy materials, these conveyors deliver with precision.

Is Reliability a Core Aspect of Rothe Packtech's Pallet Conveyor Design?

Reliability is the backbone of Rothe Packtech's Pallet Conveyor design philosophy. These conveyors are engineered with meticulous care to deliver unwavering performance. By minimizing downtime and ensuring consistent productivity, Rothe Packtech's Pallet Conveyors emerge as your steadfast partner for material transport.

Why Choose Rothe Packtech as Your Pallet Conveyor Manufacturer?

- Innovation as Standard: Rothe Packtech is committed to creative innovation, and this commitment is deeply ingrained in their Pallet Conveyor systems. These conveyors are designed to be cutting-edge solutions that continuously push the boundaries of material transport.

- Customization for All: Rothe Packtech understands that industries vary, and one size does not fit all. Their Pallet Conveyor systems are highly customizable, ensuring they align perfectly with your unique requirements.

- Trust and Confidentiality: Building long-lasting customer relationships based on trust and confidentiality is a cornerstone of Rothe Packtech's mission. They tackle your challenges with precision and discretion, ensuring your success remains their top priority.

What Makes Pallet Conveyors Essential in Modern Material Transport?

- Efficient Handling: Pallet Conveyors are champions in maintaining efficient and streamlined material flow. Their design ensures items move seamlessly, contributing to uninterrupted operations.

- Versatility in Application: These conveyors can adapt to a wide range of materials, making them indispensable in industries spanning manufacturing, logistics, e-commerce, and more.

- Precision Performance: Rothe Packtech's Pallet Conveyors offer precise control over material movement, reducing errors and elevating overall efficiency.

- Enhanced Productivity: With the capability to handle heavy loads and optimize operations, these conveyors significantly increase overall productivity.

How Do Pallet Conveyors Contribute to Sustainability in Material Transport?

In an era where sustainability is paramount, Rothe Packtech's Pallet Conveyor systems are designed with energy efficiency and waste reduction as top priorities. These systems actively contribute to a greener, more sustainable future for material transport operations by minimizing energy consumption and waste generation. This commitment seamlessly aligns with the global shift toward environmentally conscious industrial practices.

What Awaits Pallet Conveyors in the Future of Material Transport?

As industries evolve, the demand for efficient and reliable material transport solutions continues to grow. Pallet Conveyors are poised to meet these evolving needs head-on. Rothe Packtech's unwavering commitment to innovation ensures that these conveyors will continue to shape the future of material transport.

Final Words

Pallet Conveyors are not just machinery; they symbolize a new era in material transport. Rothe Packtech's expertise as a Pallet Conveyor manufacturer makes them one of the best in India and a global leader. With their unwavering focus on innovation, customization, reliability, and sustainability, Rothe Packtech's Pallet Conveyor solutions are redefining the very essence of material transport.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Power Roller |

| Frame Material | SS304/MS |

| Conveyor Width | 500mm to 1500mm |

| Conveyor Length | Customized |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Speed | Upto 20m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Power Roller Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Customisable

- Low friction

- High carrying capacity

- system provide positive driving power to the product

Application ;

- Retail Industry

- Warehouse

- Chemical Industry

- Palletising

Power Roller Conveyors: Shaping the Future of Material Transport

Power Roller Conveyors have become synonymous with efficiency and innovation in the ever-evolving landscape of material transport. Rothe Packtech, based in Pune, is at the forefront of this revolution as a leading Power Roller Conveyor manufacturer. But what exactly sets Power Roller Conveyors apart, and how are they influencing the future of material transport in India and beyond? Let's delve into this compelling journey of technological marvels.

What Makes Power Roller Conveyors Essential in Modern Material Transport?

- Efficient Material Flow: Power Roller Conveyors are instrumental in maintaining a steady and efficient material flow. Their powered rollers ensure items move smoothly and without interruption.

- Versatility Personified: These conveyors can handle a wide range of materials, making them invaluable in industries spanning logistics, e-commerce, manufacturing, and more.

- Precision Handling: Rothe Packtech's Power Roller Conveyors are engineered to precisely control material movement, reducing errors and optimizing overall efficiency.

- Boosting Productivity: With the ability to handle heavy loads and streamline operations, these conveyors significantly enhance overall productivity.

Can Power Roller Conveyors Be Customized to Meet Unique Material Transport Needs?

In an industrial landscape where one size does not fit all, Rothe Packtech understands the importance of flexibility. Their Power Roller Conveyor systems are not only versatile but also highly customizable. This adaptability ensures that industries with varying demands can find a tailored solution to seamlessly integrate into their operations, whether precision handling delicate items or robust transport of heavy materials.

Is Reliability a Core Aspect of Rothe Packtech's Power Roller Conveyor Design?

Reliability forms the foundation of Rothe Packtech's Power Roller Conveyor design philosophy. These conveyors are meticulously engineered to provide unwavering performance, minimizing downtime and ensuring consistent productivity. When you choose a Power Roller Conveyor from Rothe Packtech, you're choosing a dependable partner for your material transport needs.

Why Choose Rothe Packtech as Your Power Roller Conveyor Manufacturer?

- Innovation Unleashed: Rothe Packtech's commitment to creative innovation is at the heart of their Power Roller Conveyors. These systems are designed to redefine what's possible in material transport.

- Tailoring Excellence: Recognizing the unique needs of industries, Rothe Packtech offers customized solutions. Their Power Roller Conveyors are adaptable to various applications, ensuring a perfect fit for your requirements.

- Trust and Confidentiality: Rothe Packtech's dedication to building long-lasting customer relationships based on trust and confidentiality ensures that your unique challenges are met with precision and discretion.

How Do Power Roller Conveyors Contribute to Sustainability in Material Transport?

In a world increasingly focused on sustainability, Rothe Packtech's Power Roller Conveyor systems are designed with energy efficiency and waste reduction in mind. These systems actively contribute to a greener, more sustainable future for material transport operations by minimizing energy consumption and waste generation. This commitment seamlessly aligns with the global shift toward environmentally conscious industrial practices.

What Awaits Power Roller Conveyors in the Future of Material Transport?

The demand for efficient and reliable material transport solutions grows as industries evolve. Power Roller Conveyors are poised to meet these evolving needs head-on. Rothe Packtech's unyielding commitment to innovation ensures that these conveyors will continue to shape the future of material transport.

Final Words

Power Roller Conveyors are more than just machinery; they represent a new era in material transport. Rothe Packtech, the best Power Roller Conveyor manufacturer, places them as pioneers in India and global leaders. With their unwavering focus on innovation, customization, reliability, and sustainability, Rothe Packtech's Power Roller Conveyor solutions are redefining the very essence of material transport.

| Business Type | Manufacturer, Exporter, Supplier |

| Belt Material | Acetyll(POM)/SS |

| Voltage | 220V/380V/415V |

| Belt Length | Customized |

| Belt Width | 82.6mm,114.3mm,190.5mm |

| Country of Origin | India |

| Conveyor Type | Slat Chain |

| Frame Material | SS304/MS |

| Conveyor Profile | Straight/Curve |

| Height | As per Requirement |

| Speed | Upto 60m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Slat Chain Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Smooth 90° Transfer

- Used for small Products

- No Product tipping

- Heat Resistant"

Application :

- Lane Diverter

- Liquor Industry

- Pharma Industry

- Food Industry

- Dairy Industry

Slat Chain Conveyors: Transforming Material Handling In Pune And Across India

Material handling is a critical aspect of industries in Pune and nationwide. To address the evolving needs of this sector, Rothe Packtech introduces Slat Chain Conveyors. This article delves into the world of Slat Chain Conveyors, exploring their innovative features and how they reshape material handling processes.

What Sets Slat Chain Conveyors Apart In Material Handling?

Slat Chain Conveyors are at the forefront of material handling technology. They feature a unique design with interlocking slats or plates, which form a continuous surface for conveying items. This design provides exceptional stability, making Slat Chain Conveyors ideal for transporting heavy or irregularly shaped loads.

How Do Slat Chain Conveyors Enhance Material Handling Precision?

In material handling, precision is essential, and Slat Chain Conveyors excel in this aspect. The individual slats ensure that products are conveyed with accuracy and minimal deviation. Whether transporting delicate items or ensuring precise assembly line processes, Slat Chain Conveyors provide the necessary control.

How Does Rothe Packtech Cater To Unique Material Handling Requirements?

Understanding that each industry has distinct material handling needs, Rothe Packtech collaborates closely with clients, thus being the best Slat Chain Conveyor manufacturer. These solutions are tailored to specific requirements, optimizing processes for particular products and streamlining complex handling tasks.

How Does Rothe Packtech Prioritize Safety In Material Handling?

Safety is paramount in material handling operations, and Rothe Packtech ensures it remains a top priority. Slat Chain Conveyors have advanced safety features, including emergency stop mechanisms, sensors, and protective guards. These measures minimize the risk of accidents and provide a secure working environment for operators.

How Does Rothe Packtech Promote Sustainability In Material Handling?

Sustainability is a pressing concern today, and Rothe Packtech addresses it through Slat Chain Conveyor systems. These systems are created with energy efficiency in mind and environmental impact. By minimizing waste and energy usage, Rothe Packtech contributes to a greener and more sustainable future for material handling operations.

What Lies Ahead For Slat Chain Conveyors?

As industries in Pune, India, and beyond continue to demand greater precision, control, and sustainability in material handling, the future of Slat Chain Conveyors appears promising. Rothe Packtech remains committed to innovation, continuously enhancing the capabilities of Slat Chain Conveyors to meet evolving industry needs.

With a strong presence in India and expanding global reach, Rothe Packtech is poised to lead as the top Slat Chain Conveyor manufacturer. These conveyors are set to play a pivotal role in the future of material handling, empowering businesses to achieve higher levels of precision, control, and sustainability.

Final Words

Slat Chain Conveyors represent a leap forward in material handling technology. Rothe Packtech's expertise in manufacturing these advanced systems positions the company as a leader in Pune and the broader Indian market. With a focus on precision, customization, safety, and sustainability, Rothe Packtech's Slat Chain Conveyor solutions are revolutionizing material handling processes and steering industries toward a more efficient and sustainable future.

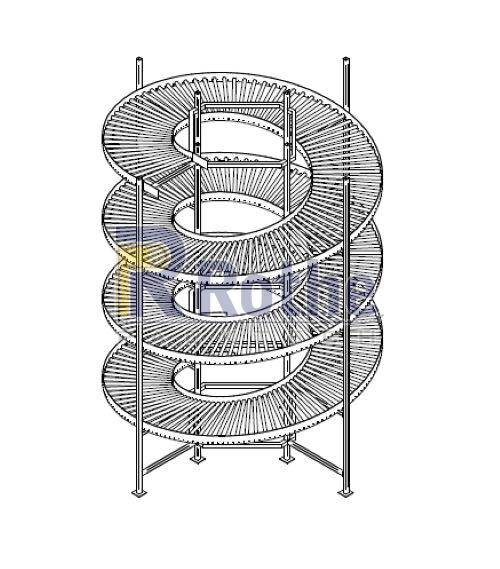

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Frame Material | SS304/MS |

| Conveyor Profile | Vertical |

| Height | Upto 10m (as per Requirement) |

| Speed | 25 Product/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | Up/Down |

We Rothe Packtech are leading manufacturer and supplier of Lowerator / Lifter / Spiral Conveyror in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- 90° vertical Transfer

- Heavy load capacity

- Minimum Surface Required

Application :

- Warehouse

- Chamical Industry

- Dairy Industry

- Food Industry

Unlocking Efficiency with Rothe Packtech's Vertical Lifter, Z Elevator, and Spiral Conveyor

In the realm of material handling and conveyance, innovation takes center stage. Rothe Packtech, a pioneer in designing and manufacturing conveyor systems, introduces remarkable solutions: the Vertical Lifter/ Z Elevator and Spiral Conveyor.

These cutting-edge systems are poised to redefine how materials are transported, elevated, and processed in Pune and nationwide. What sets these conveyors apart, and how are they revolutionizing the material handling landscape? Let's embark on a journey of discovery.

Why Choose Rothe Packtech's Vertical Lifter, Z Elevator, and Spiral Conveyor?

In the competitive industrial market, the key reasons to choose Rothe Packtech's Vertical Lifter/ Z Elevator and Spiral Conveyor would be the following points:

Rothe Packtech's commitment to innovation shines through in these conveyors, offering state-of-the-art solutions meticulously designed and tested for excellence.

Material handling needs vary across industries. Rothe Packtech understands this and provides customized conveyor systems that fulfill the unique requirements of different applications.

Trust and confidentiality are cornerstones of Rothe Packtech's customer relationships. They work discreetly and collaboratively to address challenges and ensure mutual success.

How Do Vertical Lifter, Z Elevator, and Spiral Conveyor Enhance Material Handling Efficiency?

These conveyors are engineered to redefine efficiency in material handling. They offer precise control over the elevation and transportation of materials and optimize overall efficiency. Whether you're vertically transporting delicate components or processing materials in a spiral, these conveyors are the linchpin of streamlined material handling processes.

Can These Conveyors Be Customised to Suit Unique Material Handling Needs?

The diversity of material handling operations demands flexibility. Rothe Packtech understands this and offers highly customizable conveyor systems. Whether transporting fragile goods, processing materials in a spiral configuration, or elevating materials with precision, these conveyors can be tailored to seamlessly integrate into your specific material handling operations.

How Do These Conveyors Promote Safety in Material Handling?

Safety is paramount in material handling operations, and Rothe Packtech prioritizes it. Their conveyor systems have advanced safety features, including emergency stop mechanisms, real-time monitoring sensors, and robust protective guards. These measures create a secure working environment, allowing operators to focus on productivity without safety concerns.

Are The Vertical Lifters, Z Elevators, and Spiral Conveyors Fit For Scalable Businesses?

As industries in cities like Pune and beyond continue to change, the demand for efficient material handling solutions, including these conveyors, is rising. Rothe Packtech's unwavering commitment to innovation ensures that these systems remain at the forefront of material handling advancements.

Vertical Lifter, Z Elevator, Spiral Conveyor, and even Metal Detector Conveyor systems represent the next chapter in the ongoing story of material handling, where adaptability and innovation work harmoniously to propel industries toward even greater productivity and success.

Final Words

Rothe Packtech's Vertical Lifter, Z Elevator, and Spiral Conveyor systems aren't just machines; they are architects of a new era in material handling. Rothe Packtech's expertise in manufacturing these cutting-edge systems positions them as pioneers in India and global leaders in the material handling industry.

With their unwavering focus on excellence, customization, safety, and innovation, Rothe Packtech's conveyor solutions are redefining the essence of material handling, maximizing efficiency and profitability for their valued customers.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Take Off |

| Belt Material | PVC/PU/Rubber |

| Frame Material | SS304/MS |

| Belt Width | 300mm to 1200mm |

| Belt Length | Customized |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Speed | Upto 25m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Take Up Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Inclined/Declined Conveyor

- Floor to floor transfer

- Robust Design

Application :

- Retail Industry

- Warehouse

- FMCG Industry

Take Up Conveyors: Shaping the Future of Material Handling

Take Up Conveyors have emerged as the linchpin of efficiency and reliability in the ever-evolving material handling landscape. Rothe Packtech, a trailblazing Take Up Conveyor Manufacturer, stands as the pioneer of this transformative wave. But what exactly makes Take Up Conveyors an indispensable force in material handling? Let's delve into this innovative marvel.

What Sets Rothe Packtech Apart as a Take-Up Conveyor Manufacturer?

- Crafting Excellence: Rothe Packtech is synonymous with creative innovation. Their Take Up Conveyors are meticulously designed and crafted to meet the highest standards.

- Customization as a Cornerstone: In a world where one size does not fit all, Rothe Packtech offers tailor-made solutions. Their Take Up Conveyors can be customized to address the unique demands of diverse industries and applications

- Long-term Partnerships: Rothe Packtech is committed to forging enduring client relationships. Their dedication to confidentiality ensures that each customer's unique challenges are addressed with personalized solutions.

Can Take-Up Conveyors Be Customized to Address Unique Material Handling Challenges?

In a world where material handling challenges are as diverse as the industries they serve, Rothe Packtech, as the best Take Up Conveyor Manufacturer, understands the importance of flexibility. Their Take Up Conveyor systems can be tailored to meet the precise requirements of multiple industries, ensuring seamless integration into the heart of your operations. Whether you're handling delicate materials or heavy loads, these conveyors adapt effortlessly to cater to your unique needs.

Is Reliability at the Core of Rothe Packtech's Take-Up Conveyor Design?

Reliability is non-negotiable in material handling, and Rothe Packtech takes it to heart. Their Take Up Conveyors are engineered for unwavering reliability, minimizing downtime, and ensuring consistent productivity. With Rothe Packtech, you're not just investing in a conveyor; you're investing in a dependable partner for your material handling needs.

Why Are Take-Up Conveyors Essential in Material Handling?

- Ensuring Tension Control: Take Up Conveyors play a pivotal role in maintaining the proper tension of conveyor belts, which is crucial for efficient material handling.

- Enhanced Belt Lifespan: By effectively controlling tension, these conveyors contribute to the prolonged lifespan of conveyor belts, reducing maintenance and replacement costs.

- Precision and Consistency: Take-up conveyors provide precise tension control, ensuring that materials are transported consistently and without disruptions.

- Optimized Efficiency: Rothe Packtech's Take Up Conveyors are designed to maximize efficiency, increasing overall productivity.

How Do Take Up Conveyors Contribute to Sustainability in Material Handling?

In a world where sustainability is paramount, Rothe Packtech's Take Up Conveyor systems are designed with energy efficiency and waste reduction in mind. By minimizing energy consumption and waste generation, these systems play a crucial role in advancing a greener and more sustainable future for material handling operations. This commitment aligns seamlessly with the global shift towards environmentally conscious industrial practices.

What Does the Future Hold for Take Up Conveyors in Material Handling?

As industries in Pune and beyond evolve, the demands for efficient and reliable material handling solutions grow. Take Up Conveyors remain at the forefront of this evolution, and Rothe Packtech's unwavering commitment to innovation ensures that these conveyors will continue to shape the future of material handling.

Final Words

Take Up Conveyors are not just machines but the architects of a new era in material handling. Rothe Packtech's expertise in manufacturing these cutting-edge systems positions them as pioneers in India and global leaders. With their relentless focus on efficiency, customization, reliability, and sustainability, Rothe Packtech's Take Up Conveyor solutions are redefining the essence of material handling.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Belt Width | 300mm To 500mm |

| Type | Telescopic |

| Belt Length | Customized |

| Voltage | 220V/380V/415V |

| Belt Material | PVC/PU/Rubber |

| Frame Material | SS304/MS |

| Conveyor Profile | Straight |

| Height | As per Requirement |

| Speed | Upto 60m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Telescopic Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Compact Design

- Various product unloading position

Application :

- Pouch Collation

- Product Sorting

- FMCG Industry

Telescopic Conveyors: Redefining Material Handling Horizons

Telescopic Conveyors have emerged as a symbol of innovation and efficiency in the ever-evolving realm of material handling. Rothe Packtech, a pioneer in conveyor systems, leads the charge as a Telescopic Conveyor manufacturer. But what makes Telescopic Conveyors so unique, and how are they shaping the material handling landscape? Let's embark on a journey to discover these remarkable marvels.

What Sets Rothe Packtech Apart as a Telescopic Conveyor Manufacturer?

- Innovative Excellence: Rothe Packtech embodies creative innovation in every aspect of their Telescopic Conveyor systems, pushing the boundaries of what's possible.

- Solutions For All Industries: In a world where unique challenges abound, Rothe Packtech thrives on customization. Their Telescopic Conveyors can be tailored to meet the specific demands of diverse industries and applications.

- Reliable Partnerships: Rothe Packtech's commitment to building long-lasting relationships based on trust and confidentiality ensures that each client's unique needs are addressed with the utmost care and precision.

Can Telescopic Conveyors Be Customized for Unique Material Handling Needs?

In a world where industrial challenges are as diverse as the products they handle, Rothe Packtech understands the importance of flexibility. Their Telescopic Conveyor systems can be tailored to suit specific requirements, making them a versatile choice for industries with varying needs. Whether it's precision handling of fragile goods or robust transport of heavy loads, these conveyors adapt seamlessly to cater to unique demands.

Is Reliability at the Core of Rothe Packtech's Telescopic Conveyor Design?

Reliability is a cornerstone of Rothe Packtech's Telescopic Conveyor design philosophy. These conveyors are engineered for unwavering reliability, minimizing downtime, and ensuring consistent productivity. When you invest in a Telescopic Conveyor from Rothe Packtech, you invest in a dependable partner for your material handling needs.

Why Are Telescopic Conveyors Essential in Modern Material Handling?

- Space Optimization: Telescopic Conveyors are experts in maximizing space utilization, allowing efficient material handling even in confined areas.

- Increased Efficiency: With their extendable design, these conveyors significantly reduce the time and effort required for loading and unloading materials.

- Versatile Applications: Telescopic Conveyors adapt seamlessly to various industries, from warehousing and logistics to manufacturing

- Enhanced Productivity: Rothe Packtech's Telescopic Conveyors are engineered for peak performance, increasing overall productivity and streamlining material handling processes.

How Do Telescopic Conveyors Contribute to Sustainability in Material Handling?

In an era where sustainability reigns supreme, Rothe Packtech's Telescopic Conveyor systems are designed with energy efficiency and waste reduction in mind. By minimizing energy consumption and waste generation, these conveyors play a vital role in advancing a greener and more sustainable future for material handling operations. This commitment perfectly aligns with the global shift towards environmentally conscious industrial practices.

What Awaits Telescopic Conveyors in the Future of Material Handling?

As industries in Pune and beyond evolve, the demands for efficient and reliable material handling solutions grow. Telescopic Conveyors remain at the forefront of this transformation, and Rothe Packtech's unwavering commitment to innovation ensures that these conveyors will continue to redefine the future of material handling.

Final Word

Telescopic Conveyors represent more than just machinery; they are the architects of a new era in material handling. Rothe Packtech's expertise as the top Telescopic Conveyor manufacturer makes them a pioneer in India and a global leaders. With their relentless focus on innovation, customization, reliability, and sustainability, Rothe Packtech's Telescopic Conveyor solutions are reshaping the very essence of material handling.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Agriculture Industry |

| Country of Origin | India |

| Type | Trough Belt |

| Frame Material | SS304/MS |

| Conveyor Width | 400mm to 2000mm |

| Conveyor Length | Customized |

| Conveyor Profile | Straight/Incline |

| Height | As per Requirement |

| Speed | 10m/min |

| Motor | Bongfiglioli/SEW/ABB/Elecon/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

| Direction | One |

We Rothe Packtech are leading manufacturer and supplier of Trough Belt Conveyor in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit :

- Conveying high tonnage of material

- Handles Gradual inclines for long runs

- Require low maintenance

- High efficiency

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Shape | Rectangular |

| Color | Grey |

| Usage | Industrial |

| Certification | CE Certified |

| Voltage | 220V |

| Type | Vertical |

| Phase | Single Phase |

| Country of Origin | India |

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Belt Material | PVC/PU/Rubber |

| Frame Material | SS304/MS |

| Rejection | Pneumatic Pusher/other type as per aplication requirement |

| Direction | One |

| Weighing Device | Load Cell |

| Pressurized Air | 5 to 6 Bar |

| Capacity | upto 25Kg |

| Accuracy | ±10 Gm |

| Belt Length | As per Product |

| Conveyor Profile | Straight |

| Height | Upto 700mm |

| Speed | Upto 45m/min |

| Motor | Bongfiglioli/SEW/ABB/equivalent |

| Motor Position | Right/Left |

| Voltage | 220V/380V/415V |

| Hertz | 50Hz/60Hz |

| VFD | Mitsubishi/AB/Siemens/Delta/equivalent |

We Rothe Packtech are leading manufacturer and supplier of Weighing Conveyor (Static) in India | Rothe Packtech Pune Maharashtra India.

Features And Benefit ;

- Product Weight check

- Weight accuracy

- High Speed

- Product Rejection

Application :

- FMCG Industry

- Pharma Industry

- Food Industry

- Brewry Industry

- Liquor Industry

- Dairy Industry

Weighing Conveyors from Rothe Packtech Precision and Efficiency Combined

In the world of industrial operations, accuracy and efficiency are paramount. Weighing Conveyors, designed and manufactured by Rothe Packtech, are redefining material handling processes across Pune and beyond. But what sets Rothe Packtech apart as a Weighing Conveyor Manufacturer, and how do these conveyors transform the industry?

What Makes Rothe Packtech the Go-To Weighing Conveyor Manufacturer?

Rothe Packtech's reputation as a top Weighing Conveyor Manufacturer stems from its unwavering commitment to excellence and innovation. With years of experience and a team of dedicated experts, Rothe Packtech has perfected the art of designing and crafting Weighing Conveyors that deliver precise and efficient material handling solutions.

What Are the Benefits of Using Weighing Conveyors to Improve Material Handling?

Weighing Conveyors play a pivotal role in material handling operations, ensuring that products are accurately weighed and sorted. Rothe Packtech's Weighing Conveyors excel in efficiency by combining state-of-the-art weighing technology with seamless conveyor systems. This integration guarantees that products move swiftly through the conveyor while being accurately weighed, minimizing errors and optimizing production processes.

Can Rothe Packtech Meet Their Weighing Conveyor Solutions to Unique Needs?

In the diverse landscape of industries, each business has unique material handling requirements. Rothe Packtech understands the importance of tailoring solutions to fit specific needs. As a leading Weighing Conveyor Manufacturer, Rothe Packtech collaborates closely with clients to customize Weighing Conveyor systems. Whether you need precise weight measurements for small items or bulk materials, Rothe Packtech's Weighing Conveyors can be adapted to your precise requirements.

Are Rothe Packtech's Weighing Conveyors Setting New Standards?

Precision and Efficiency: Rothe Packtech's Weighing Conveyors redefine material handling with precise weight measurements and efficient sorting capabilities.

Cutting-Edge Technology: These conveyors integrate advanced weighing technology seamlessly into the conveyor system, reducing errors and optimizing production.

A Step Ahead: Rothe Packtech's commitment to innovation keeps their Weighing Conveyors at the forefront of industry standards, continuously pushing the boundaries of precision and efficiency.

When It Comes To Environmentally Friendly Practises, How Do Weigh Conveyors FitIn?

- Sustainability by Design: Rothe Packtech's Weighing Conveyor systems are engineered with sustainability in mind, reducing energy consumption and minimizing environmental impact.

- Curbing Waste: Rothe Packtech is taking active steps toward a greener future for material handling operations by optimizing material handling processes and curbing waste generation.

- Aligning with Green Initiatives: : Rothe Packtech's commitment to sustainability aligns perfectly with the growing global shift toward environmentally conscious practices in the industry.

What Does the Future Hold for Weighing Conveyors in Material Handling?

As industries continue to demand greater precision and efficiency in material handling, the future of Weighing Conveyors looks promising. Rothe Packtech remains committed to innovation, continuously enhancing the capabilities of Weighing Conveyors to meet evolving industry needs.

These conveyors are set to play a pivotal role in the future of material handling, empowering businesses to achieve higher levels of precision, efficiency, and sustainability.

Final Words

Weighing Conveyors represent a leap forward in material handling technology, and Rothe Packtech's expertise in manufacturing these advanced systems positions the company as a leader in the industry. With a focus on precision, customization, safety, and sustainability, Rothe Packtech's Weighing Conveyor solutions are revolutionizing material handling processes in India and driving industries toward a more efficient and sustainable future.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Finishing | Polished |

| Usage | Industrial |

| Certification | CE Certified |

| Voltage | 220V |

| Type | Z Type |

| Country of Origin | India |

| Phase | Single Phase |